GENERAL DESCRIPTION

CONVENTIONAL SYSTEMS

FOR CHECKING IF REPAIRS TO ION-EXCHANGE MEMBRANES HAVE BEEN SUCCESSFULLY

CARRIED OUT ARE LENGHTHY, COSTLY, AND IMPERFECT.

GENERALLY, A PRELIMINARY CHECK IS MADE BY EXAMINING THE PERIPHERY OF THE

PATCH THAT HAS BEEN REPAIRED AND TOUCHING IT, TO SEE IF IT HAS BEEN WELDED

PROPERLY.

OF COURSE,

THIS TYPE OF CHECK IS NOT ENTIRELY RELIABLE, AS THE OPERATOR CANNOT BE

CERTAIN THAT THERE ARE NO PERFORATIONS DUE TO POOR WELDING.

THE OPERATOR THUS RUNS THE RISK OF RE-FITTING A FAULTY MEMBRANE TO AN

ELECTROLYZER, WICH IS HIGHLY DANGEROUS AND MAY HAVE SERIOUS CONSEQUENCES.

THE OTHER CHECKING SYSTEM – USING A WATER FRAME OR VACUUM PLATES (SUCH

AS OUR HOLLY MACHINE) – MAKE IT OBLIGATORY FOR THE OPERATOR TO CHECK THE

ENTIRE MEMBRANE (THUS INCURRING INSTALLATION TIME) TO TEST JUST A FEW

SQUARE CENTIMETRES, FURTHER STRESSING THE MEMBRANE.

THUS THERE IS A NEED FOR A LOCAL CHECK THAT IS FAST AND SAFE AND THAT

ENABLES THE OPERATOR TO CHECK HIS REPAIRS WITHOUT REMOVING THE MEMBRANE

FROM THE REPAIR ZONE. THIS IS WHERE HOSMY COMES INTO ACTION.

HOSMY IS A SYSTEM FOR CHECKING THE ZONES WHERE MEMBRANES HAVE BEEN REPAIRED.

HOSMY ALLOWS YOU TO CHECK IF THE REPAIR HAS BEEN MADE PROPERLY, AND THAT

THERE ARE NO PERFORATIONS.

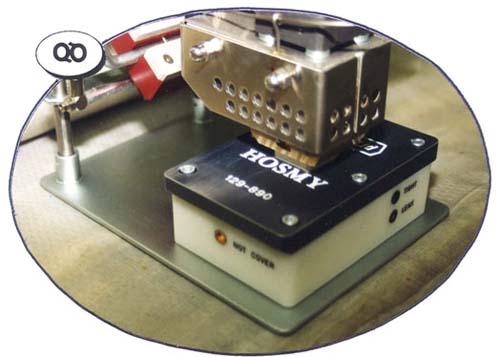

AFTER HAVING PLACED HOSMY ON THE CENTERING FRAME OF THE WELNY WELDER (WHICH

HAS JUST COMPLETED A REPAIR), THE OPERATOR MUST PUSH THE TWO START PUSH-BOTTON

(HOW A STANDARD WELDING REPAIR) ; IT STARTS TO TEST IN AUTOMATIC WHEN

THE HEATING PLATE OF WELNY MACHINE TOUCH HOSMY AND THE GREEN INDICATOR

LIGHTS UP. THE OPERATOR MUST BE WAIT MIN. 5 SEC. MAX. 25 SECONDS FOR THE

RESULT OF THE CHECK.

IF HOSMY’S GREEN INDICATOR LIGHTS REMAIN, THIS MEANS THAT THE REPAIR HAS

BEEN SECURELY WELDED AND THE MEMBRANE HAS NO PERFORATIONS IN THAT ZONE.

IF ALSO THE RED INDICATOR LIGHTS UP AN AUDIBLE SIGNAL IS SOUNDED, WHICH

MEANS THAT THE WORK HAS NOT BEEN DONE PROPERLY AND THE REPAIR STILL HAS

MICRO PERFORATIONS. IN THIS WAY YOU CAN REFIT YOUR MEMBRANES IN THE ELECTROLYZER

WITH COMPLETE CONFIDENCE AND SAFETY.

HOWEVER IN BOTH SITUATION AFTER 25 SECONDS THE GREEN AND RED INDICATOR

LIGHT GO DOWN.

ADVANTAGES

HOSMY IS SUPPLIED READY FOR USE.

NO INSTALLATION TIME IS INVOLVED.

THE DEVICE IS BATTERY POWERED, SO THERE ARE NO PROBLEMS WITH ELECTRIC

CABLES, WIRE, TUBES, ETC.

HOSMY GUARANTEES THAT YOUR REPAIRS ARE PERFECTLY SEALED IN FEW SECONDS.

HOSMY’S FOOTPRINT COMBINES PERFECTLY WITH THE CENTERING FRAME OF THE WELNY

WELDER, SO YOU DON’T HAVE TO WORRY ABOUT POSITIONING.

HOSMY IS EASY TO USE.

TECHNICAL SPECIFICATIONS

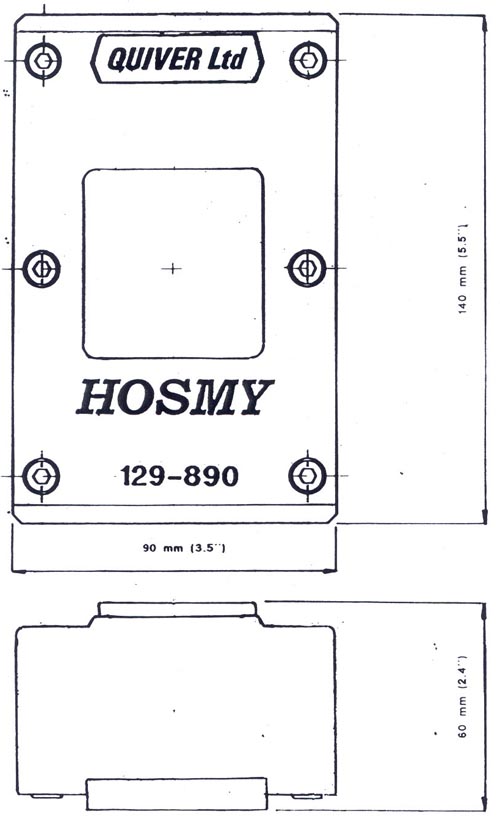

· OVERAL DIMENSION: 140 mm (5.5") x 90 mm (3.5") x 60 mm (2.4")

· VOLTAGE BATTERY 9 VDC

· WAIT CHECK TIME MIN. 5 SECONDS

· WAIT CHECK TIME MAX. 25 SECONDS

· COLOR TIGHT LED GREEN

· COLOR LEAK LED RED

· MASS 1 Kg (2.2 lb)

· HOSMY COLOR BLUE AND WHITE

· ALL MATERIAL ENVIROMENT RESISTENCE AND G-SHOCK

· GASKET SILICON MATERIAL

· SAFETY UNDER CE RULE TESTABLE WELDING REPAIR MEMBRANE

· ASAHI CHEMICAL

· ASAHI GLASS

· DU PONT MEMBRANE PARAMETERS OF USE NOT NECESSARY CALIBRATIONS TREATEMENT

BEFORE TESTING

· REMOUVE KAPTON FILM FROM THE WELDING PATCH

· CHECK IF THE SURFACE OF CENTERING PLATE IS CLEANE INSTALLATION AND OPERATING

PROCEDURE

· REMOUVE KAPTON FILM FROM THE WELDING PATCH

· CHECK IF THE SURFACE OF CENTERING PLATE IS CLEANE

· OPEN THE VACUUM PUMP

· CLOSE THE SPECIAL FITTING NEAR THE COLLECTOR

· PUT HOSMY ON THE CENTERING PLATE WITH THE FOOTPRINT INSIDE THE WINDOW

· PUSH THE TWO START PUSH-BOTTON OF THE WELNY MACHINE

· THE GREEN LED LIGHTS UP · HOSMY START ITS TEST

· WAIT MIN.5 – MAX. 25 SECONDS

· IF THE WELDING REPAIR IS AT TIGHT THE GREEN LED LIGHTS REMAIN

· IF THE WELDING REPAIR SHOW A LEAK ALSO THE RED LED LIGHTS UP AND HOSMY

EMITTED AN AUDIBLE SIGNAL

OVERALL DIMENSIONS