![]()

GENERAL DESCRIPTION

KIT KAPTON PN 126-470 KAPTON FILM IS USED DURING THE WELDING REPAIR.

THIS FILM PROVIDE TO PROTECTION THE MEMBRANE, BUT IN THE SAME TIME PERMIT

THE TRANSMISSION OF THE TEMPERATURE GENERATED BY HEAT PLATE OF THE WELDING

MACHINE.

THE SAME FILM CAN BE UTILIZED IN MORE OF ONE REPAIR.

ITS TRANSLUCID

ORANGE COLOUR PERMIT TO SEE THE CENTER MARKER ON THE MEMBRANE TO MAKE

THE WELDING REPAIR IN THE CENTER OF THE MEMBRANE PERFORATION.

COMPOSITION KIT :

- 10 SHEET A4 (210 x 297 mm / 8" x 11")

- STORED IN INDIVIDUALLY PROTECTED BETWEEN SOFT PAPER

- ANY SHEET IS MAKER WITH A PART NUMBER 128-126

TECHNICAL SPECIFICATION

KAPTON TYPE HN

| FILM THICKNESS |

50.

8 micron

|

| TENSILE STRENGTH AT 23°C (MINIMUM) |

165

NEWTON / mm²

|

| ELONGATION (MINIMUM) |

45%

|

| SHRINCAGE (MAXIMUM) |

2.5%

|

| MOISTURE ABSORPTION (MAXIMUM) |

4.0%

|

| DIELECTRIC STRENGTH AC (MINIMUM) |

197

KV / mm

|

| BRECKDOWNVOLTAGE AC (MINIMUM) |

10.000

V

|

| VOLUME RESISTIVITY AT 200° |

10

^ 12 O/cm

|

| DIELECTRIC CONSTANT AT 1 KHz (MAXIMUM) |

3.9

|

| DISSIPATION FACTOR AT 1 KHz (MAXIMUM) |

0.0036

|

GENERAL DESCRIPTION

GREASE PN 122-054

QUIVER LTD RACCOMANDED TO USE GREASE PN 122-054 DURING THE WELDING OPERATION

FOR THIS REASON:

- THE MEMBRANE SHOULD

BE WASHED OFF OR SOAKED IN DEIONIZED WATER BEFORE THE REPAIR IS MADE

THE SURFACE NEEDS ONLY TO BE BLOTTTED IN THE AREA TO BE PATCHED, TO

REMOVE ANY VISIBLE WATER. A VERY LIGHT COATING OFF GREASE PN 122-054

SHOULD BE APPLIED ON TOP OF THE THERMAL INSULATOR ( KAPTON SHEET A4

PN 126-470) POLYIMIDE FILM OF THE UPPER HEATING PLATE.

THIS GREASE PROVIDES FOR HEATHER PLATE RELEASE AND SHOULD BE CHECKED BEFORE EACH HEAT SEAL.

"ATTENTION NOT PUT THE GREASE BETWEEN THE PATCH AND THE MEMBRANE, THE MEMBRANE BECOME UNWELDABLE". - DURING THE HEAT

SEALIN OPERATION, THE THERMAL INSULATOR (KAPTON SHEET) FILM PROTECTOR

ON THE UPPER HEATHER PLATE MUST BE SLIK OR SLIGHTLY GREASY WITH GREASE

TO ALLOW PROPER RELEASE.

"ATTENTION NOT PUT THE GREASE BETWEEN THE PATCH AND THE MEMBRANE, THE MEMBRANE BECOME UNWELDABLE". - IF THE MEMBRANE

DEING PATCHED MAKES CONTACT WITH ANY PART OF THE HEATING HEAD OUTSIDE

OF THE HEAT ZONE (40 x 40 mm OR 32x80 mm), THEN THIS CONTACT AREA MAY

ALLOW HEAT TRANSFER AND THE MEMBRANE WILL BECOME DISTORTED AS IN FIGURE

1.

THIS DISTORTION SHOW UP AS WRINKLES IN A "RIPPLE WAVE" TYPE PATTERN. THESE CAN BE CORRECTED BY EITHER: WIPE A VERY SMALL AMMOUNT OF GREASE PN 122-054 BETWEEN EACH OF THE THERMAL INSULATOR FILM (KAPTON SHEET) AND THIR RESPECTIVE HEATING PLATE (40 x 40 mm OR 32 x 80 mm).

"ATTENTION NOT PUT THE GREASE BETWEEN THE PATCH AND THE MEMBRANE, THE MEMBRANE BECOME UNWELDABLE".

TECHNICAL SPECIFICATION

| COULEUR |

BLANCHATRE,

TRANSLUCIDE

|

| DENSITE' A' 20°C |

ENVIRON

1,0

|

| PENETRATION TRAVAILEE', ENVIRON (NORME ASTM D 217) |

220

|

| PENETRATION APRES 24h DE REPOS, ENVIRON |

200

|

| FLUAGE EN 24h A 200° C, % |

<

6

|

| EVAPORATION EN 24h A 200°C |

<

2

|

| RIGIDITE' DIELECTRIQUE ENVIRON (NORMES AFNOR NF C 26230 ET CEI 250) |

20

KV / mm

|

| CONSTANTE DIELECTRIQUE, A 1 kHz (NORMES AFNOR NF C 26230 ET CEI 250) |

2,6

|

| FACTEUR DE DISSIPATION DIELECTRIQUE A 1 kHz, ENVIRON (NORMES AFNOR NF C 26230 ET CEI 250) |

5.10

^ -4

|

| TEMPERATURE LIMITES D'EMPLOI |

-

40 a +200°C

|

REMARQUES : LE GREASE PN 122-054 REPOND AUX NORMES MILITAIRES MIL S 8660 ET OTAN S 736.

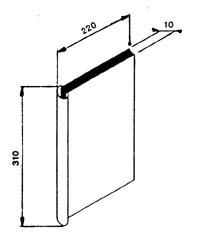

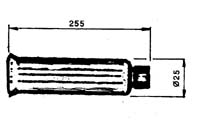

OVERALL DIMENSIONS Devices protected by international patents

|

|

|

ALL RIGHT ARE LEGALLY PRESERVED, DIRITTI RISERVATI, RIPRODUZIONE PARZIALE VIETATA