|

|

| Fondstuffs - HANDLING OF HEAT-SHRINK WRAPPED SAUSAGE PRODUCTS - HANGING OF HAM - PALLETIZING OF COFFEE PACKAGES IN SAND PATTERNS - FILLING OF CARTONS WITH BOTTLES |

Foundries

- APPLICATION OF CORES IN SHELL MOULDING - SPRAYING OF RELEASING AGENT IN MOULDS - SPRAYING OF GRAPHITES AND BENTONITES - REMOVAL OF SLAG FLOATING ON BATHS OF MOLTEN LEAD AND ANTIMONY INGOTS |

| Automative

Applicantions - APPLICATION OF SEALENT ON HEADLAMPS - POLYURETHANE INJECTION - DEPALLETIZING OF COMPONENTS - PREPARATION OF WIRING |

Forging

- AS AID TO FORGING HAMMERS IN SCISSORS PRODUCTION - AS AID TO PRESSES FOR WIRE ROPE ACCESSORIES - DIE CLEANING |

| Testing

- CONTROL PANELS, SCARY ACTUATES THE PUSH BUTTONS AND LEVER/KNOB-OPERATED CONTROLS DIRECTLY - IN LOW TEMPERATURE, AIR-CONDITIONED CHAMBERS (-40°C) |

Wood |

| Electrical

Household Appliances - APPLICATION OF ADHESIVE BANDS - APPLICATION OF GASKETS DIRECTLY DEPOSITED BY EXTRUSION - SCREWING-IN OF COVERS - FEEDING OF EDGE BANDING MACHINES |

Machine

Tools - UNLOADING AND PALLETIZING - DEBURRING - TRANSFER FROM ONE MACHINE TO THE NEXT |

| Die-Casting

- UNLOADING OF PRESSES AND CUTTING OF GATING / RISERS - SPRAYING OF LUBRICATING AND RELEASING AGENTS - APPLICATION OF INSERTS |

Sheet

Metal Working - UNLOADING AND PALLETTIZING - SHEET FEEDING |

| Dye

Works - LOADING / UNLOADING OF MATERIAL HOLDER SPOOLS - PALLETIZING OF SPOOLS |

Glass

- UNLOADING OF BLOW MOULDING MACHINES - FILLING OF CARTONS - PREPARATION OF CARTONS |

| Reinforced

Plastics - SPRAYING OF GLASS FIBRES AND RESIN - COMPACTING - TRIMMING |

· ROBOTS OF THE SCARY SERIES ARE OFFERED AS ALTERNATIVES IN HIGH PRODUCTION FOR MANUAL HANDLING OR MATERIAL HANDLING SYSTEM OF CLASSIC DESIGN ON FOR SPECIFIC APPLICATIONS.

· SCARY IS A DEVICE DESIGNED INDEPENDENTLY FROM THE APPLICATION, HENCE WITH SPECIFIC HIGH QUALITY AND WELL PROVEN COMPONENTS

· BY APPROPRIATE PROGRAMMING IT IS POSSIBLE TO PERFORM A VERY HIGH NUMBER OF MOVEMENTS AS THEY ARE OBTAINED SIMPLY BY PROGRAMMING POINTS.

· THE PATHS CAN BE TRACED IN ANY DIRECTION BY PROGRAMMING THE TWO END POINTS IN SPACE.

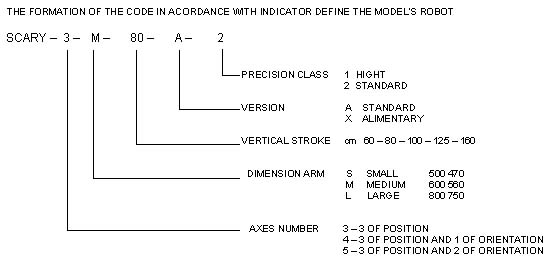

AVAILABLE MODEL

PERFORMANCE

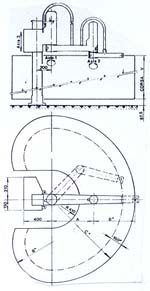

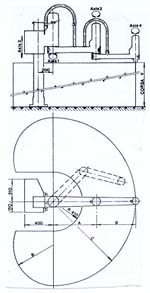

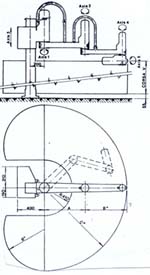

POSITION AXES: N° 3

ORIENTATION AXES (IN ACCORDANCE WITH MODEL): N° 4 - 5

PNEUMATIC INPUT ON-OFF (GRIP): N° 1 - 2

VERTICAL STROKE

(IN ACCORDANCE WITH MODEL): mm 600 - 800 - 1000 - 1250 - 1600

ORIZZONTAL STROKE

(IN ACCORDANCE WITH MODEL): mm FROM 1000 TO 2000 TRANSVERSAL STROKE (IN

ACCORDANCE WITH MODEL): mm FROM 700 TO 1250 VERTICAL SPEED (IN ACORDANCE

WITH MODEL): m/sec. 1

ORIZZONTAL SPEED: m/sec. 1

MOVEMENTABLE LUMP: Kg. 25

RESOLUTION VERSION 1 HIGHT: mm 0.1 mm

RESOLUTION VERSION 2 STANDARD: mm 0.5 mm

PROGRAM AUTONOMY WITHOUT SUPPLY: 2000 hours

AUTOTESTING AT MISSING POWER

MESSAGE SHOWED ON THE CN MONITOR OF THE FOLLOWING CONDITION:

· PROGRAMM

· EXECUTIVE

· CYCLO

· AXIS SELECTED ERROR

· QUOTE SELECTED AXIS

· TYPE OF ALLARM

MECHANICALS FEATURES

STANDARD MODEL :

· BRUSHLESS MOTOR WTH ENCODER INSIDE

· ARM TRASMISSION TROUGHT COAXIAL MOTOR GEAR WITH REDUCED PLAY

· VERTICAL TRASMISSION TROUGHT PIGNON/TOOTHED BELT

· VOLVENT GUIDE

· ZERO AXES

· COLUMN OF STEEL

· ARM IN COMPOUND MATERIAL/SOFT ALLOY

· PNEUMATIC TAKING GRIP

· GRIP HOSE INCORPORATED

ALIMENTARY MODEL :

ALL THE SAME OF STANDARD MODEL EXCEPT :

· EXTERNAL MATERIAL INOX

· WASHABLE TROUGHT WATER JET OR STEEM

SUPPLY

SUPPLY VOLTAGE: 380 V 50 Hz 3 PHASE

POWER CONSUMPTION: 3 kVA

ELECTRICAL PROTECTION: IP 54

COMPRESSED AIR: 6 bar

MANUFACTURED: UNDER CE RULE

CLICK HERE TO SEE A BIG TECH DRAWING