GENERAL DESCRIPTION

WEPA4-350 IS A PATCH

FOR REPAIRING ION EXCHANGE PERFLUORINATED MEMBRANE.

THE BIG SIZE OF WEPA4-350 IS NECESSARY WHEN ON THE MEMBRANE THERE ARE

MANY TEAR, TYPICALLY NEAR THE GASKET, WHERE THE MEMBRANE IS MORE STRESSED

INSIDE THE ELECTROLYZER.

WITH WEPA4-350 IS POSSIBLE TO REPAIR THIS TEAR STEP BY STEP WITH A LITTLE

BIT OVERLAP DURING THE WELDER OPERATION.

SOMETIME THIS PROCEDURE IS USED ALSO TO REINFORCE THE EXTERNAL PERIMETRAL

OF THE MEMBRANE, TYPICALLY STRESSED DURING THE REASSEMBLE AND ASSEMBLING

IN THE ELECTROLYZER.

ADVANTAGE

· REPAIR EXTENDE TEAR

· CATHODE SIDE MARKED

COMPOSITION KIT

- WEPA4-350 PN 128-783

NBR. 10 SHEET A4

PATCH SIZE :

210 mm x 297 mm

PATCH MATERIAL

DUPONT NAFION 350

· PERFLUOROSULFONIC ACID CATION EXCHANGE MEMBRANE OF OUTSTANDING CHEMICAL

RESISTANCE FOR A VARIETY OF ELECTROLITIC PROCESSES.

· STRONGER FIBER REINFORCEMENT THAT 324 IT HAS OTHERWISE THE SAME COMPOSITION

OF SULFONIC ACID POLIMER

PROPERTIES :

· REINFORCEMENT: TEFLON

· IONIC FORM: H+

· RESISTANCE IN 0.6N KC1 AT 23°: C 3.7 (O-cm²) ²

· WEIGHT CALIBER AT 20 °C, 50% RH: 4.0 (g/dm ²)

· LINEAR EXPANSION FROM 50% RH AT 23 °C TO WATER, 23 ° , IN H+ FORM

· MACHINE DIRECTION: 5 - 7 %

· TRANSVERSE DIRECTION 6 - 8 %

WELDABLE MEMBRANE

WITH WEPA4-350:

· DUPONT MEMBRANE (APPROVED BY DUPONT)

· ASAHI GLASS MEMBRANE (TESTED BY EUROPEAN BUILDING CONTRACTOR

OF CHLORO ALKALI PLANT AND CHLORO ALKALI MANUFACTURER)

· ASAHI CHEMICAL MEMBRANE (TESTED BY EUROPEAN BUILDING

CONTRACTOR OF CHLORO ALKALI PLANT AND CHLORO ALKALI MANUFACTURER)

OPERATING PROCEDURE

FOR GOOD JOINING WITH WEPA4-350 AND CONSISTENTLY SAFE WORKING CONDITION, QUIVER LTD RACCOMANDED AS FOLLOWS:

· OPEN THE VACUUM

PUMP BEFORE WELDING TO PRESERVE THE OPERATOR HEALTH, A VACUUM SYSTEM PROVIDE

TO ASPIRE OVER AND UNDER DIRECTLY FROM PATCH AREA AND TO COLLECT THE NOXIOUS

HEAT FLUORINATED GASES DURING WELDING AND COOLING OPERATION.

· CLEAN THE ZONE OF THE MEMBRANE TO BE REPAIRED AS DESCRIBED IN THE WELNY

WELDER MAINTENANCE AND USE.

· USE A MEMBRANE OR SCRAPS OF MEMBRANE OF THE SAME TYPE TO BE REPAIRED

IN ORDER TO REACH THE RIGHT COMPROMISE BETWEEN THE NECESSARY PARAMETERS

OF THE WELNY WELDING MACHINE.

· WELDING TIME

· COOLING TIME

· WELDING PRESSURE

· HEATING PLATE TEMPERATURE

WE RACCOMANDED TO CUT A STRIP OF WEPA4-350 AS FOLLOWS:

FOR HEATING-PLATE

40 x 40 mm : STRIP WIDTH 35 mm

FOR HEATING-PLATE 32 x 80 mm : STRIP WIDTH 27 mm

BESIDES TO PROTECTION THE MEMBRANE AND THE PATCH DURING THE WELDING OPERATION IS SOLELY NECESSARY TO LEAN A KAPTON'S SHEET WITH THE SIZE ABOUT 100 mm x 150 mm IN THE LOWER SIDE OF THE CENTERING PLATE, THAT WILL REMAIN IN THE POSITION BY THE SUCTION GENERATED FROM VACUUM PUMP.

INDICATIVE GUIDE PARAMETERS FOR EACH STEP

· WELDING TIME FROM

2 TO 3 min'

· COOLING TIME

FROM 1 TO 2 min'

· WELDING PRESSURE FROM 3 TO 4 bar

· HEATING PLATE TEMPERATURE FROM 200 TO 350° C

THE ABOVE DESCRIBED VALUES ARE GIVEN AS A GUIDE ONLY BECAUSE IS NOT POSSIBLE TO DETERMINATE STANDARDIZED PARAMETERS FOR ALL THE MEMBRANES AS THESE DEPEND OF THE TYPE OF MEMBRANE, THE AMMOUNT OF WEAR, MOISTURE AND ROOM TEMPERATURE.

HENCE IT IS UP TO THE OPERATOR (BY CARRYING OUT SOME TESTES) TO OPTIMIZE THE PARAMETERS ON SCRAP MEMBRANES OR ON A SAMPLE IN ORDER TO ARCHIVE HIGH QUALITY JOINING.

AT THIS POINT YOU CAN PROCEEDE TO REPAIR YOUR MEMBRANES WITHOUT PROBLEMS AND WITH OPTIMUM RESULT.

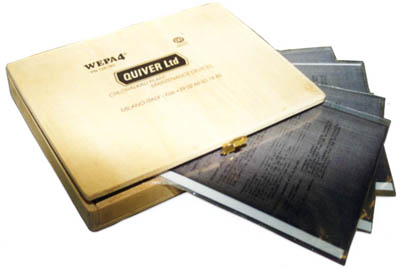

OVERALL DIMENSION AND STORAGE OF KIT WEPA4

B0X DIMENSION

: 230 x 320 x 15 mm

WEIGHT: 500 g

INDIVIDUALLY PROTECTED

AD HERMETICALLY SEALED WITH POLYETHYLENE FILM.

WEPA4-350 PATCHS HAVE TO BE STORED UNDER CONDITION OF RELATIVE UMIDITY

60/80% AND TEMPERATURE FROM 16 TO 20° C.

THE KIT IS SUPPLIED IN A RUGGED AND PRATICAL CASE OF HIGH QUALITY WOOD

WITH RELATIVE CATCH.