GENERAL DESCRIPTION

THE CONVENTIONAL ION

EXCHANGE PERFLUORINATED MEMBRANES REPAIR SYSTEM REQUIRES A LENGTHY PROCEDURE

FOR PREPARATION OF THE PATCH.

THE CUTTING OF THE PATCH, OF THERMAL INSULATOR FILM, RECOGNITION OF THE

CATHODE AND ANODE SIDES AS WELL AS CENTERING ARE DECISIVE FACTOR FOR SUCCESSFULL

JOINING.

MOREOVER QUITE A PART FROM THE OPERATOR’S PREPARATION, IT IS EASY

TO MAKE ACCIDENTAL MISTAKES.

ALL THIS EINTAILS LENGTHY MAINTENANCE TIMES AS WEEL AS RISK OF FAULTY

JOINING.

FOR THIS REASON WEPAC WAS DEVELOPED.

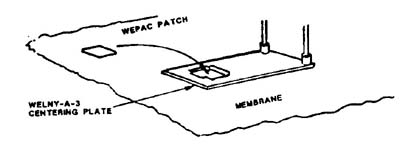

WEPAC AS BEEN DESIGNED TO BE USED SPECIFICALLY ON WELDING MACHINES OF

THE WELNY SERIES.

IS

ABLE TO PUT DIRECTLY IN THE CENTERING PLATE OF THE WELNY-A-3 WELDER

GUARANTEED CENTER

NOT PERMITTED INVERSION

ERROR

COMPOSITION KIT

– WEPAC – 523 – PN 128-128

NBR. 50 WEPAC 40

x 40 – N350 – PN 128-124

PATCH SIZE :

35 x 35 mm

PATCH SIZE :

27 x 75 mm

THERMAL INSULATOR

SIZE : 37 x 85 mm

THERMAL INSULATOR SIZE : 45 x 45 mm

PATCH MATERIAL

:

·

PERFLUOROSULFONIC

ACID CATION EXCHANGE MEMBRANE OF OUTSTANDING CHEMICAL RESISTANCE FOR A

VARIETY OF ELECTROLITIC PROCESSES.

·

REINFORCEMENT: TEFLON

·

MACHINE DIRECTION: 5 – 7%

·

TYPE: HN

·FILM

THICHNESS: 50.8 µm

· TENSILE

STRENGTH AT 23°C: Min. 165 N/mm²

·

ELONGATION: Min. 45 %

·

SHRINCAGE: Max. 2.5 %

·

MOISTURE ABSORPTION: Max. 4.0 %

·

BRECKDOWNVOLTAGE AC: Min. 10 000 V

·

DIELECTRIC CONSTANT AT 1 kHz: Max. 3.9

WELDABLE MEMBRANE WITH WEPAC :

DUPONT MEMBRANE(APPROVED BY DUPONT)

ASAHI CHEMICAL MEMBRANE (TESTED BY EUROPEAN BUILDING CONTRACTOR

OF

·

USE A MEMBRANE OR SCRAPS OF MEMBRANE OF THE SAME TYPE TO

BE REPAIRED IN ORDER TO REACH THE RIGHT COMPROMISE BETWEEN THE NECESSARY

PARAMETERS OF THE WELNY WELDING MACHINE.

-

WELDING TIME

·

WELDING TIME: 2/3 min.

THE ABOVE DESCRIBED

VALUES ARE GIVEN US A GUIDE ONLY BECAUSE IS NOT POSSIBLE TO DETERMINATE

STANDARDIZED PARAMETERS FOR ALL THE MEMBRANES AS THESE DEPEND OF THE TYPE

OF MEMBRANE, THE AMMOUNT OF WEAR, MOISTURE AND ROOM TEMPERATURE.

HENCE IT IS UP TO

THE OPERATOR (BY CARRYING OUT SOME TESTES) TO OPTIMIZE THE PARAMETERS

ON SCRAP MEMBRANES OR ON A SAMPLE IN ORDER TO ARCHIVIE HIGH QUALITY JOINING.

AS THIS POINT YOU

CAN PROCEEDE TO REPAIR YOUR MEMBRANES WITHOUT PROBLEMS AND WITH OPTIMUM

RESULT.

OVERALL DIMENSIONS AND STORAGE OF KIT WEPAC

BOX

DIMENSION : 100 x 60 x 100 mm

THE KIT IS SUPPLIED IN A RUGGED AND PRATICAL CASE OF HIGH QUALITY WOOD WITH RELATIVE CATCH.