|

GENERAL DESCRIPTION

|

THESE PROBLEMS HAVE

GIVEN RISE TO THE NEED FOR A STIRRER WITH TWO OR MORE STATIONS, BUT WITH

THE SIZE OF A SINGLE-STATION MODEL. THUS WIRBY WAS CONCEIVED.

20-STATION STIRRER COMPACT SIZE.

VERTICAL ARRANGEMENT

OF THE STATIONS.

PROGRAMMABLE WITH DIFFERENT CYCLES:

1) VARIABLE SPEED

2) STOPS CALCULATED FOR RESTING OF THE SUBSTANCES

3) MANUAL/AUTOMATIC FILLING

4) SOFTWARE INTERFACE WITH THE MOST FREQUENTLY USED TRANSMISSION PROTOCOLS

5) THE STIRRER CAN BE INSTALLED INSIDE ROBOT-CONTROLLED CAROUSELS

6) VERY LIGHT WEIGHT: THE STIRRER IS EASY PORTABLE IN THE VARIOUS LABORATORIES

OR CAN BE INSERTED BY ROBOT-CONTROLLED CAROUSEL INTO ANOTHER WITHOUT TRANSPORT

OR SET-UP COSTS.

7) INTEGRATED MICROPROCESSOR MAKES THE STIRRER FULLY INDEPENDENT WITHOUT

AID OF PLC OR NUMERICAL CONTROL.

8) THANKS TO THE CORROSION-PROOF AND COMPOSITE MATERIALS OF CONSTRUCTION,

THERE IS NO RISK OF EXTERNAL CONTAMINATION OF THE STIRRER OR DAMAGE TO

THE SUBSTANCES BEING PROCESSED. THANKS TO ITS ATTRACTIVE DESIGN THE STIRRER

ALSO FINDS PLACE IN THE MOST PRESTIGIOUS LABORATORIES.

ORBITABLE SWING RADIUS:

1 mm

NOMINAL FREQUENCY:

20 Hz

MAX FREQUENCY: 45 Hz

MIN. FREQUENCY: 6 Hz

CENTRIFUGAL ACCELLERATION AT 20 Hz : 1,44 g

POSITION TOLLERANCE OF THE ROBOT DURING THE LOAD OF MICROPLATES IN ANY

DIRECTION: + / - 1 mm

AVAILABLE MICROPLATES

DIMENSIONS: 127 x 85 x 14 mm

STRUCTURE IN

WELDING STEEL GALVANIZED AND PAINTED

NBR. 04 SHOCK-ADSORBER WITH STUD BOLT M 8 x 25 mm

MOTOR PARTS

DC ELECTRIC MOTOR

TRASMISSION

AT TOOTHED BELT

ECCENTRIC SHAFTS

SUPPORT WITH

VOLVENT SEAL BEARING

AUTOMATIC DEVICE OF OPENING FOR THE LOCK FINGER

LIMIT SWITCH LOCKED FINGER OPEN

MAIN SWITCH WITH RED

LUMINOUS LAMP

TEST PUSH BUTTON

(SHAKE AT 20 Hz)

IF PUSH SHAKE, IF RELEASE STOPS

LAMP SHAKER IN ACTION : YELLOW

INTERFACE CONNECTOR

WITH CN/PLC

1 PIN LOCKS

OPEN TO PLC

1 PIN READY

TO PLC (SHAKER STOPS)

3 PIN FOR 8 SHAKER FREQUENCY FROM PLC

1 PIN GND

SPEED CONTROL DRIVER

FUSE

SUPPLY PLUG GND WITH CABLE 2 mm ² 220 v - 50 Hz

SHAKER PARTS

SUPPORT WITH

SEAL VOLVENT BEAR

STRUCTURE IN

LIGHT OXIDATION ALLOY

NBR. 20 MICROPLATES SUPPORT

NBR. 20 LOCK FINGER OPENING OF 12 mm TO PERMIT AT ROBOT HANDLE TO ENTRANCE

|

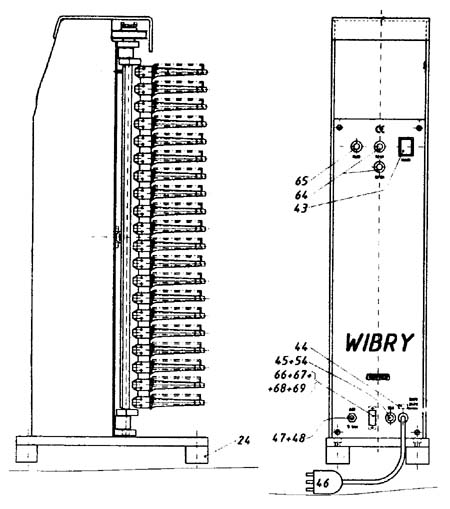

INDEX DESCRIPTION 65 RUN PUSH BUTTON 64 TEST / OPEN PUSH BUTTON 43 MAIN SWITCH 44 GND PIN 45 - 54 OVER CHARGE PROTECTION 66-67-68-69 SOFTWARE INTERFACE 47-48 AIR COMPRESSED SUPPLY 46 MAIN SUPPLY VOLTAGE 24 MAIN FRAME |

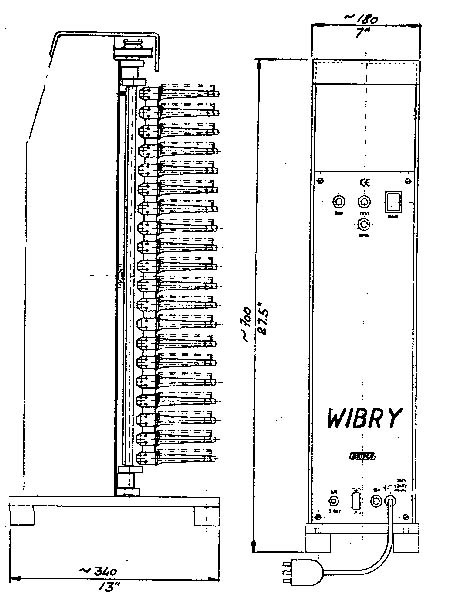

OVERAL DIMENSIONS